Your Next Breakthrough is Closer Than You Think

Speaker:

Please welcome to the stage senior marketing manager for Siemens, Patrick Farrell,

Patrick:

Hello, everybody. Um, again, I am, I’m also excited to win the telescope here a little bit ago, my son will be excited about that. Now the trick is going to be, how am I going to get that back to Detroit on the airplanes? The task ahead. So I’m here to talk about today is really about what are we doing for innovation? How can you innovate more? And I’ll start with one of the most famous innovators of all time, Thomas Edison. So as he developed the light bulb, it’s how he took, you know, maybe a thousand tries before he got to the right combination that for a successful light bulb. And so our reporter asked, you know, one of the Thomas and asked him, how did it feel to fail 1000 times? And of course, Thomas says I didn’t fail. Really. The light bulb was an investment that took just 1000 steps.

Patrick:

So really well, what can we do to, to engineer innovation more into our products? What can you be do to be more like Thomas Edison, but do it in a fraction of the time. It took him to do it simulation and big computing are a big part of that. And we’ll help you do that today. And I think it was, we’ve heard from a number of the presentations we’ve heard today and yesterday. And we we’ve heard that a lot, how simulation has been able to help them, they’re able to innovate, run many different iterations. And so what I’m going to talk about over the next course of these next few minutes is how simulation, it has really been part of, one of the really original drivers of big computing. I’ll give you a little bit of history of where simulation is coming from and where it’s going with the, the increase of computing power as it’s gone over the decades.

Patrick:

So for those of you who are not familiar with engineering simulation, let me give a little very brief, very basic explanation of what it is. So in terms of engineering simulation, it’s not the physics generators that you might see in games, or just kind of make things look like they’re happening in real life. Really engineering simulation is very much founded in mathematics. Specifically a lot of them, one of the major areas of mathematics is finite element analysis. And basically what that, what engineering simulation does is it’s actually measuring how products perform. We’re trying to find out what the stresses are. If a product is going to actually break, how, how different pieces move together, how does fluid flow through different types of geometry? So we’re really doing very detailed types of analysis. It’s not just for pretty pictures or for show. So it starts with basically geometry.

Patrick:

So your designer would create a basic geometry like you see here, this is just a very basic metal bracket. Then basically the engineer would take that. And the finite element method, what that does is it takes that geometry and it gets remodeled. We need to remodel it into various small elements basically. So we need to discrete ties that model. And basically each of those places where the elements intersect the nodes, where the points come together, essentially you have six degrees of freedom, and then you multiply that across all the different number of nodes. And that essentially gives you the number of equations that need to be solved. So that’s essentially why we’ve always needed computing power to be able to solve this. Cause you can easily get the thousands, hundreds of thousand millions. And now we’re up to the billions of degrees of freedom that need to be solved on these models. Um, then you also apply your loading and your boundary conditions. So here it’s fixed at the bottom, some pressures or forces up at the top and then you simulate it. So you submit that to the computer. It solves, it runs a number that does all the calculations and then you get back some results. So you can actually see how the part deforms where it stresses are, and make sure that it’s meeting the product requirements that you’ve designed this part for.

Patrick:

So find the element analysis, really kind of the foundation for a number of different types of physics simulation. That’s what I’m really talking more specifically about. Of course, there’s lots of other simulations like, like we’ve seen, you know, with, with software simulation as well as getting into controls and looking at, you know, autonomous vehicles. But what I’m really talking about in this case is physics based simulation. So structures, structural analysis, dynamics, durability, um, you know, getting into composites, CFD, thermal flow, uh, motion, multi body dynamics, which is really more about seeing how different mechanisms move. And then these can also be applied to acoustic. So in general, this whole area is really considered computer aided engineering or commonly known as CA.

Patrick:

So the history of CAE really dates back. I mean the finite element method, the mathematical method, it started with developed in the forties. So before computers even existed, but nobody could really use it again because of know you’ve got to calculate hundreds, thousands of equations at that time to be able to do anything. So it wasn’t really until the fifties when the first computers like the IBM 7-0-1 that you see here in the picture came about, and you can start being able to perform this. Now, what’s also interesting about this picture. You see, there’s no monitor, there’s no graphics, there’s no fancy 3d graphics. So the way people used to have to make those models in the past were actually by hand, they would take the CAD drawing. Or now that you’re in the CAD drawings, the drafting drawings, and basically trying to map out where those nodes, where the elements would be in space, put them into punch cards and you kind of see the woman they’re up in front, she’s got a stack of, of cards.

Patrick:

And so usually what, a lot of times what we call a finite element model today are decks. So you have a deck of cards. That’s where the terminology comes from. And then they feed that into the computer and then it performs the calculations and then you get the results back and you need to interpret the results. So simulation has really been, um, a driver to big computing. I mean, this was state of the art technology, you know, 60 years ago, more than 60 years ago. So simulation has really been at the forefront, really pushing computing power as far as it could go. And it really wasn’t until the 1960s is when things really started to heat up. So during the space race, it was when, finite analysis became really important because obviously trying to build and break large rockets is that physically possible. It’s hard. You’re dealing with environments that are not, we’re not able to really physically test. So another reason why assimilation is also important, it was to help beat the Russians to market. So being able to do the simulation means they’re not having to do that, that builder break, you can iterate more, get more finding out, making sure that your, your designs are meeting performance. So there was another critical component. And that’s why, again, also simulations used today is a competitive advantage against the competitors, the competitors that you have out there.

Patrick:

Simulation has been constantly pushing the hardware capabilities. And, but one of the other things we need to keep in mind is all simulations are wrong. Simulation, especially the finite element method is really an approximation method. So they’re all basically just estimates. It’s just that some simulations are better than others. And there’s a lot of assumptions that go into to building these models. Um, so the, the, the model on the left is actually the picture on the left. I mean, this is the, both of these pictures are actually, the two same simulations, but the one on the left was done in 19 early 1990s. These are fluid dynamics simulations here, cause some water flowing out of a kind of a reservoir. You see that? So based on the computing power, I mean, simulation is always, has been really hampered by the competing power at that state.

Patrick:

So we’ve had the, you know, the mesh that you saw in there, I’m going to finer meshes means more equations. So we haven’t been able to get really fine methods, which means you’re obviously not capturing all the, the full fidelity of a model, whereas, you know, on the right, the image on the right is something that was done in and around circa 2010. So you can kind of see the difference in terms of fidelity of how simulation is, has him changed over time. So the one on the left eye, you could see that elements is they’re quite large elements. You can see how it’s broken down. It’s a two D model instead of a three D model. And you can see even by the results, they look quite different than one on the right. You see a lot more fidelity, you can kind of see the waves and the splashing and thing of the liquid coming out.

Patrick:

So computing of power has allowed us to increase fidelity of the models and get closer to accuracy and being able to predict performance much more closer to reality than we have been before. But another part of computing that, um, you know, people don’t necessarily think of that actually impacts the entire CAE analysis process. So a big part, as I mentioned of performing CE or finite element analysis is the modeling process itself. So understanding how much elements you have on your model, you also need to make sure that your element quality is correct. Otherwise I can also skew screw up your results. So a big part of the CAE process is actually analysis modeling. And you can, if you look at the entire CE process itself, sometimes that analysis modeling step can take as long as up to 80% of the entire process.

Patrick:

And that’s even including the solve time, which depending on the type of model, it can be a very long process. So, you know, the analysis modeling step can be broken down into a number of different steps. So if you consider you’re taking that CAD geometry, a lot of times, what you need to do is get rid of a lot of features that aren’t necessary to perform the analysis. It, because one of the reasons if you’ve got small holes in your model, for example, you try to put a mesh on that. Then you’re essentially introducing lots of little nodes are on that hole, which again, increases your, theories of freedom, increase the number of equations you have. And it’s going to take longer to solve that model. And there might be cases where the small holes really not important to really what you’re trying to solve for that particular part.

Patrick:

You’re probably trying to find stress maybe in another area of that part. So a lot of times what engineers need to do is they need to simplify that geometry, if they’ve got, they’ll need to take out those small holes, take out the small fill is a, if they’ve got a thin walled part, they need to maybe change that solid body into a surface or sheet bodies in there. So they can put a shell meshes on it, which would also make the solving run faster. So there’s a lot of work that goes in just even preparing the geometry, getting it ready for mash. The next step, doing the mesh takes a long time. So, you know, trying to get the right element quality, trying to get a, if you’ve got a very large, complicated model, like a car body, or your frame that you’re trying to match fully, even just creating the mesh can take a bit of computing power to create the, on some of those on those pieces. And nowadays we’re moving to some more automated things, but it still takes some computing power and taking, creating that match. I mean, some of these large models could take weeks months even just to create the model before they’re ready to solve it.

Patrick:

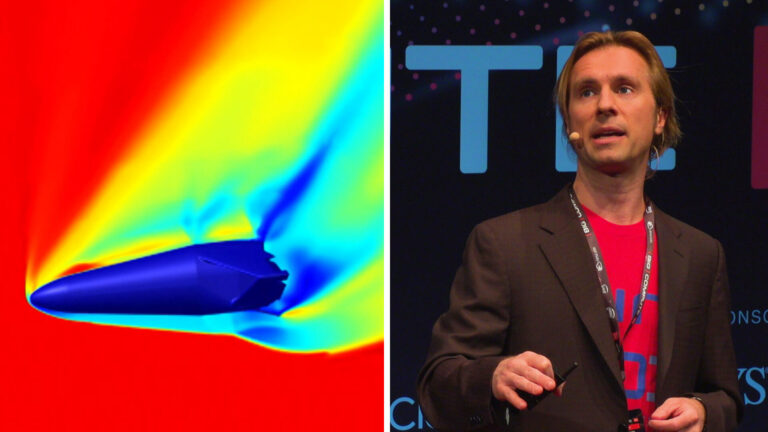

So how does big competing then really push simulation for me now? So now as, as competing power gets more advanced, we’re able to do, obviously the obvious change is going to be in terms of fidelity. So this is a much more modern simulation that we’ve seen, uh, something that we’ll see starts to see him plus, which has the CFD code against. So you’re seeing some of the air, how it flows based off where it’s coming out of the wheels and how then it falls around the car in the back. So you mean the obvious answer for, you know, how it be competing, helps simulation. The first one, doesn’t always obviously fidelity the next thing. And I was also again how it improves analysis modeling. So now we can, if you’ve got very large competing resources that are means we can start putting much smaller elements.

Patrick:

And if we can get to point where we’re getting really infant testimony, smile, and it’s, maybe we don’t even need to worry about element quality as much. So that means we can speed the analysis process. We don’t need to worry about how bigger, what our element quality is. We can also use the power to generate these larger messages and really get that analysis prior analysis modeling process time and drive it down and get to the results quicker, which is where they were engineers want to be able to spend their time in it and look at the results, understanding what sort of design changes they need to make to their, to their products.

Patrick:

So up until this point, I’ve been talking about various specific simulation domains, but obviously in the real world simulation or physics domains, don’t just happen in silos. So everything’s happening at once simultaneously. So structures doesn’t happen in silos. CFD doesn’t happen in the silos. So if you think in terms of really what happens when airflow over goes over airplane wing, or in this case, a car spoiler, you’ve got an airflow that goes over that spoiler, it creates pressures. The pressures of that structure are then going to deform that wing. So that wing deforms that’s going to change the air flow or the wings. So they got to rerun that, and then it’s going to change the pressure. So it’s this constant cycle that needs to happen. And so we need to also start bringing a coupling these types of simulations together, which has really been quite a challenge up to this point for a couple reasons.

Patrick:

One obviously is it’s a computing power to do that. It takes, I mean, even just to run a basic CFD analysis can take hours or days on some of these more complicated types of geometry. But now you want to try to couple that with different types of physics solver, that’s even going to take up even more competing power, but even from the software side to integrate these types of workflows, to set that up and be able to perform the analysis, to get those two, to talk to each other, is it takes a significant amount of effort from the software vendor. So we’re also working towards integrating these more so we can do more real world types of multi physics analysis like you see here.

Patrick:

So another thing is in terms of, you know, we talk about Edison and looking at variations, let me hear that again from Boom and none of the other people that I’ve talked to, or that have given presentations here. Now we want it to be able to look at thousands of iterations. And so what we can do is we can automate the simulation. We can parameterize the model so that they, we can quickly update them. And now if you’ve got large computing resource, now you can send these off in parallel or in some cases, if some need to be sequentially, it can do that, but it really allows you then to automate and be able to look at literally thousands, even hundreds of thousands, maybe of design variations. So in those cases, example, you see here, it’s automating some of the dimensions of the spars that are underneath the wing and some other properties of the simulation model.

Patrick:

And basically each of those dots you see up in the graph are essentially one design iteration. So it’s, depending on the criteria, it’s color coding on either blue or red, it means did, or did not meet certain other performance requirements in terms of either weight or, or some of the other Mark. Like this is a margin of safety simulations. So looking at margin of safety for an airplane wing. So there’s a number of criteria it’s looking at. And so you can see quickly see which design iterations are passing, and then you can go and depending on the certain type of application that you need to supply, you can look at a graph like this and zero in on maybe what are going to be really the best designs for your particular application.

Patrick:

Sample of this in use today is with Airbus. So they were looking at an air bleed system, which basically takes some hot and cold air from the engine, mixes it together. And a lot of times that pushes that into the air conditioning system within the cabin. They had a process basically to do this without simulation or without some of the, the design of experiments types of design exploration. Like we just saw in the previous video, it would take them about six months to do that process. But now they’re able to take that process with some of the automation and large computing resources and get that down into less than two weeks and be able to really help understand and redesign that get down to get to the temperature requirements that they wanted for this air bleed system and get something in a much faster time to market that they could have otherwise done before.

Patrick:

So another area, interesting area where we’re be competing is helping is, you know, in the past, we’ve been talking about the process where a designer creates a design, and then we go simulate it well now with big computing, with an also some new software and mathematical formulations, we can do, we can use simulation to help actually drive or create new designs. So instead of starting with a design, let’s just say, okay, we’ve got a, we’ve got, we know the pack of space at a certain part needs to fit within a let’s go, just kind of put some boundary conditions on where we know the attachment points are going to be for that part. Now let’s simulate that. And basically based off structural analysis, maybe some, uh, um, performance requirements that we put in there for deflection or, or stress and strain. So on, basically we can take that.

Patrick:

And basically what it will do is it’ll run an optimization routine. So again, it’s a multi run type of job is going to take significant competing resources to get some of these shapes. So the second, so the first shape you see up there is really, um, what, what maybe somebody would a designer would have designed on his own, but the second shape you see there is really what this is, what a computer would simulate or the design shape that the computer comes up with. So based on the, the loading conditions that were placed on, on a package space that might, would just spend a big rectangle for that spot, with some attachment points there in the, and for the three bullet holes, it’s able to come up with some very unique, very organic types of shapes. Then we can take those shapes and then do some of them are more traditional types of analysis to refine that again, parameterize it a bit rerun that simulation run running multiple times, or really kind of refine it. But, you know, as you see what these kinds of shapes are based on traditional manufacturing methods, you’re not going to be able to necessarily be able to manufacture that part, but with additive manufacturing, now you can also start generating these really unique types of shapes. So now you get really lightweight shapes that will really help, you know, take the weight out of it on a airplane or automobile, really help improve fuel efficiency. Ray, they’re still very strong meeting, able to meet strength and durability requirements.

Patrick:

Now, the other aspect to simulation in the past, you know, you’ve seen a lot of pictures with airplanes and cars. So obviously simulation has been heavily used in very large industries, you know, government organizations, as well as aerospace defense automotive industries. So, but getting there’s lots of people beyond those industries that can benefit from simulation. They’re certainly, you know, people are developing golf clubs. There’s certainly simulation that can be used there to help drive golf balls farther. There’s a, you know, medical equipment suppliers out there that can benefit from simulation, but simulation has traditionally been very expensive for companies to get into the software is expensive. Plus also the hardware is even more expensive and plus they need to maintain it. They need to have staff to be able to maintain it all. And then it goes obsolete, you know, relatively quickly. The other thing is small companies.

Patrick:

Aren’t going to be using simulation all of the time. So, they’re only going to be using some of the time. Otherwise, then you’ve got a whole bunch of hardware that’s might be sitting there. That’s not useful. So with big competing, we’re able to get, you know, especially when with access through the cloud, they can get access on demand, access to that hardware. And with that also, then we’re also making some of the simulation tools available to them on demand through the cloud platforms as well. So as you see here today, we’ve got a number of our own, uh, simulation tools, our CAE, or our system simulation tool SIM center aim SIM is available as well as SIM center 3d, which is our finance element, multimedia and dynamics CFD code. That’s also available. So you can get those on demand today on Rescale. You can actually access them through your web browser without having to install any software on your machine. So it’s a great thing for small small companies to be able to get out there, get the software on demand, only use it when they need it and only pay for it when they need it.

Patrick:

So, an example of this, American axle, which is an automotive supplier, they make axles that go into cars and they need to perform a number of simulations. In this case, it was specific to a fluid domain, a fluid dynamics simulation, basically of the oil that’s within some of these axles. They need to flow around and it needs to get in the gears. And so they have one server there with like 64 cores, but a number of these simulations would take way more than that. Maybe like up to 150 cores or more. And I’m going, like yours mentioned a couple of days ago or yesterday. So they have the one server there, but they’re also sharing that with a number of other analysis teams that are doing vibration simulation and other structural simulation. So even though they’ve got maybe fairly large solver or a server, they can’t really get full access to that all the time. So they, MRI can actually really needed flexibility in order to be able to perform the fluid dynamics simulations that they needed to do. So being able to get access to that type of simulation or hardware resource to rescale, it really helps them to be able to get the flexibility they need to perform the simulations they need in the time they need it by.

Patrick:

So now we’ve, you know, we’ve reached a point where everything I’ve been talking about today is really, at this point has been about product development using the simulation in the product development world. But what happens once apart is out in the field, you know, once the part’s out there, we don’t know what’s going on with it. So something like this, you could see happen with the wind turbines out there, but now you see a lot of things where, where especially industrial machinery, everything is outfitted with sensors. So you’ve probably have heard of the internet of things. So you’ve got sensors, you’ve got wind turbines out there like this that could be outfitted with sensors, you know, and obviously servicing a wind turbine is really difficult. They’re way up high in the air, the large machines. So getting up there might take a helicopter or something to bring one of those down, to look at it.

Patrick:

So being able to understand what’s happening with that machine before, a problem like this happens, it’s useful. So you might have a sensor out there picking up some vibrations, maybe a vibration that’s maybe outside of the norm of requirements that they normally, looked at. So that sensor can send that data over to the company or the manufacturer of the wind turbine, which will then have a digital twin of their model. So the digital twin, you might’ve heard that term a bit is really comes down to a simulation model of basically what’s out there in the field. So they can take that vibration data use as load case into their digital twin. Be able to receive violate that and say, okay, this is what’s going to be the impact of this vibration. Is it going to decrease the durability of some part what’s, what’s going to be the failure problem, or what’s going to be a failure mode with this thing. Do they need to go out there and service this, when do they need to service it? So finding that kind of information on your products in the field and finding problems before problems like this happen out there.

Patrick:

So, a little bit of our pit for Siemens here, it also, you know, Siemens has been around for 180 years. We’ve been making things, you know, from gas turbines to trains, to healthcare equipment. So we’ve gotten a lot of experience in industry that we’re also baking into our then our software products and simulation tools. We’re taking that knowledge that we’ve gained from industry ourselves, putting that into the software that we’ve got, that thing then help you all with your, with your engineering and simulation needs in the future, as well as we’ve got the backbones again, for some of the big computing links with Rescale, as well as the IOT applications. So being able to take sensor data, bring that through to our data management system, bring that into the house and being able to apply those to our CA models and being able to re simulate that. So definitely looking forward, we like the, you know, bring simulation and make big competing available to everyone here and be able to then really make sure that we help you with your next breakthrough and help you realize your products. Thank you.